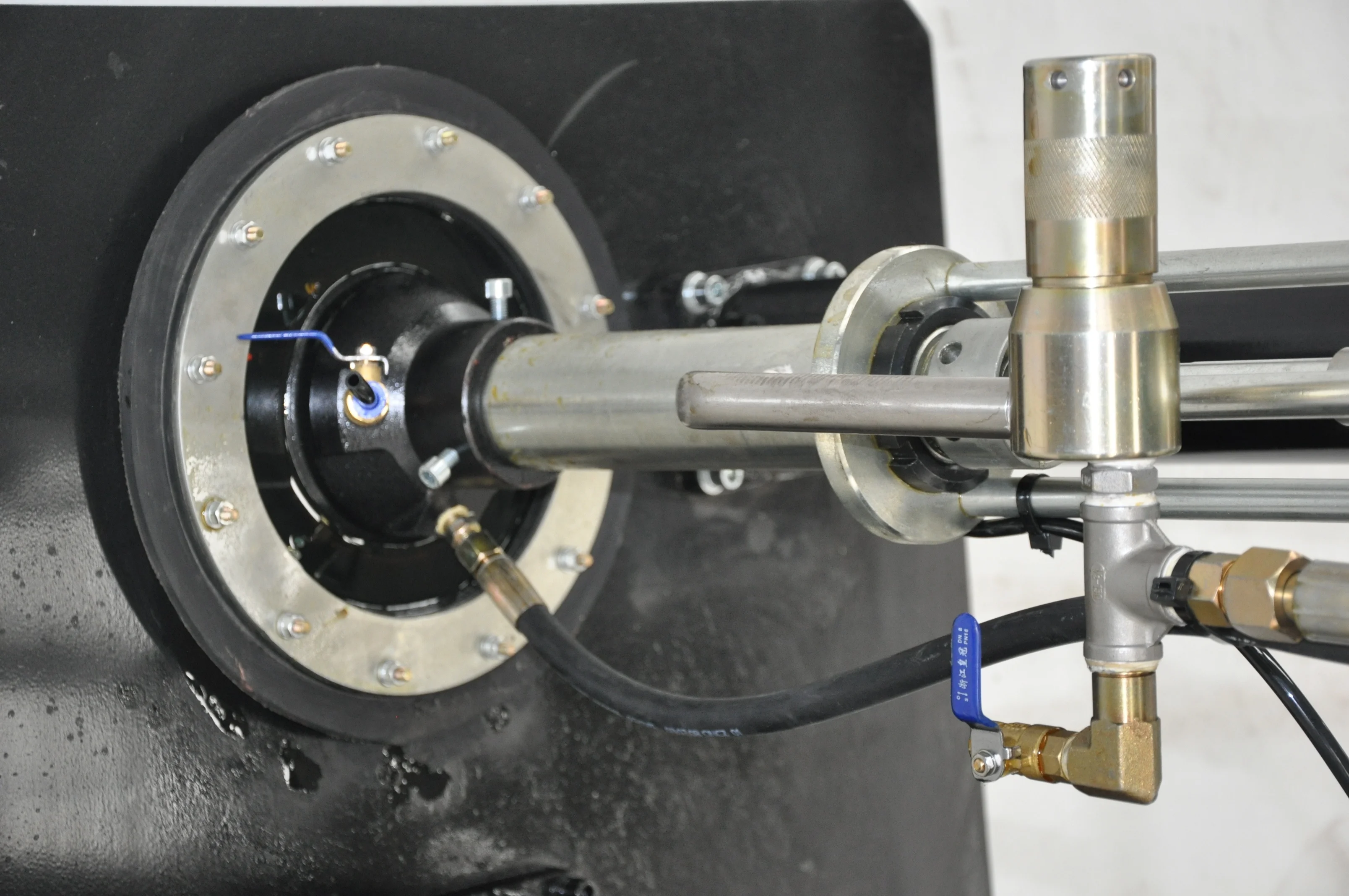

The two-component glue applicator is composed of A and B glue pumps, pneumatic system, lifting mechanism, frame, etc. Now we could introduced those parts of sealants sealing machine as follows:

1. Glue pump:

(1) A glue pump is set for each of components A and B, which are driven by their respective air motors to make a reciprocating motion to suck in and push out the glue. The glue pumps A and B are fixed together with the pressure glue plate, and then connected with the frame to form their systems.

(2) The ratio of A and B components is adjusted by a proportional lever: inward adjustment, B glue output decreases, outward adjustment, B glue output increases. By adjusting the proportional lever to control the amount of glue B, to control the ratio of A and B glue.

(3) Glue output: controlled by the air source processor, counterclockwise adjustment, the glue output increases, and clockwise adjusts the glue output to decrease. (Here refers to the total amount of glue) The glue pump adjusts the ratio of the glue amount of A and B through a proportional lever, which has the characteristics of flexible operation, stable performance, and large adjustment range.

2. Lifting mechanism: A and B component rubber pumps are respectively equipped with a set of the pneumatic lifting mechanism, which is composed of two cylinders in parallel, and the respective pump bodies are fixedly connected by a beam. One of the purposes is to apply the force of the two cylinders to the rubber surface through the pressure plate, and the pressure is adjusted by the supplier of the pressure regulating valve, generally adjusted to about 0.3MPa; second, when the rubber barrel needs to be replaced, The cylinder can lift the pressure plate. Leave the plastic bucket so that it can be replaced with a new one.