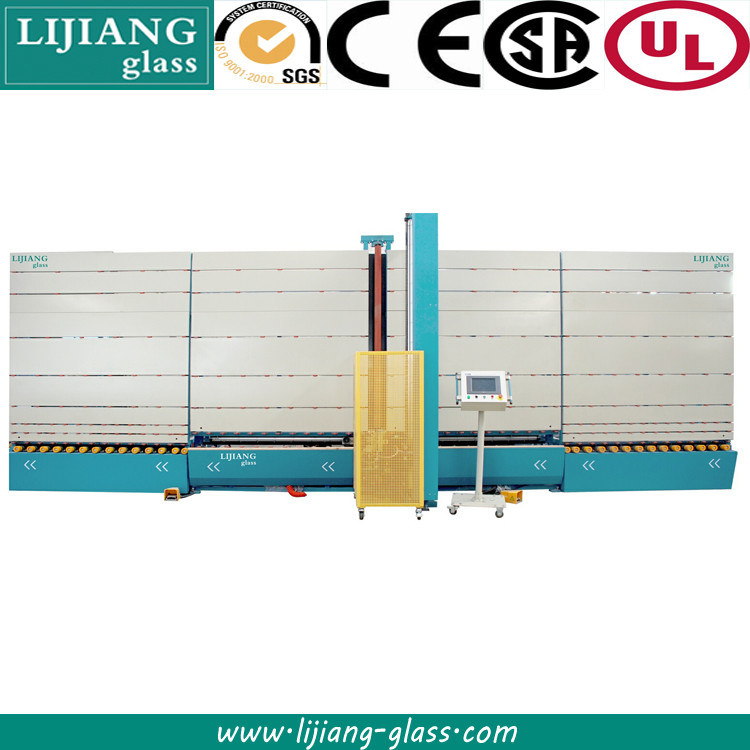

Automatic Vertical Low-e Coating Edge Deletion Machine Before Insulating Glass Production Line

LIJIANG GLASS-SERVICE FOR GLASS MANUFACTURE IN THE WORLD

Smart Vertical Low-e Edge Deleting Machine —for Low-e Glass

Smart Vertical Low-e Edge Deleting Machine is specialized for low-e glass deleting edge with vertical structure and convenient production line connection.Transmission adopts imported servo control system, accurate positioning and smooth operation. High quality grinding wheels are durable and can produce neat and beautiful grinding crack. Distance can be set among 10 ~ 150 mm arbitrarily. This machine always work together with insulating galss production line and automatic glass cutting line without low-e deletion fuction.PLC and servo motors contrl system is usefut to make machine working stable and fast.

►Main feature

1.Two-way glass access

2.Auto measure the size and the thickness

3.Auto distinguish coating side of low-e glass(optional)

4.Auto-modified function

5.The pressure of edge deleting is stable and adjustable

6.Safety protection device auto-dedusting function

7.PLC control system,touch screen interface

8.Six servo control systems

►Main technical parameter

| Transmission speed |

2~29m/min |

| Edge finish speed |

2~29m/min |

| Glass thickness |

3~15mm |

| Diameter of grinding wheel |

200mm |

| Width of grinding wheel |

10/12/15mm |

| Grinding wheel speed |

0~3000r/min |

| Min.Glass |

400×400mm |

| Max. Glass |

2500×4000mm |

| Conveyor height |

500mm |

| Total air consumption |

100L/ min |

| Total weight |

3700KG |

| Dimensions |

9700×2500×3400mm |

|

1,Transmission section

Two-way glass access,from left/right.

Auto-identification surface.

The width of edge deleting can be adjusted.

|

|

2,Electrical components

We adopt SIMENS and DELTA

|

|

Glass after edge deleting

|

|

Low-E coating checking system

|

LJBZ2535 Vertical Automatic Insulating glass production line

APPLICATION

As the most important process of insulating glass production, we are especially professional in glass cleaning, transmitting pressing and gas filling(optional).The production line can do double glass,triple glass and stepped glass.

LJBZ2535 Vertical Automatic Insulating glass production line include 7 parts: (standard model :from right to left)

1,Loading section(with low-e checking)

2,washing and drying section(can washing low-e glass)

3,conveyor section

4,checking and assembly section

5, conveyor , measure and sensor section

6,press part with gas filling

7,unloading sectionSemi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine Advantage:

Gas filling on line syetem(option)

Glass loading lifting table LJ2510P-09

Main feature

* Heavy duty design, use 380V/50HZ AC power supply

* The motor made in China,which lifting goods balancedand

* The cylinder is equipped with explosion-proof valve, when the cylinder burst can prevent the rapid decline in equipment to ensure the safe use of equipment.

* Adopts anti shearing fork design in order to prevent injury,and has overload protection function, more reliable and secure.

* Equipped with safety wedge, convenient maintenance.

* Mainly suitable for warehousing, logistics, manufacturing, maintenance and other places.

* Meetthe requirements of existing national standards of